Testing:

My test Rig:

Motherboard: Gigabyte H55N-USB3.0

Processor: Intel i5-750 2.66 ghz quad core

Disk Drive: OCZ Agility2 SSD

GPU: Sparkle GTX 480+

Case: Thelmaltake Lanbox Lite

Cooler: Intel OEM cooler.

There are many opinions on how to apply thermal grease. I like to use a razor to apply a thin layer of grease to the entire top of the processor. This ensures a conductive material for the entire effective surface of the heat sink. Not everyone considers this but there could be some minor imperfections in the plate that would effect performance. OCZ advises against this because of the new formula of their paste:

From their site:

| NO SPREADING IS NECESSARY!

1. Place a small amount of Freeze (roughly the size of a grain of rice) on the center of the IHS. 2. Lower the CPU cooler directly down onto the CPU to minimize smearing, and push it gently into place (no spreading required). 3. If necessary, the CPU cooler can be wiggled slightly to facilitate the initial spreading of the thermal compound. It may appear that only a fraction of the heat spreader has paste installed, but the cooler will squeeze the paste out to the appropriate width over time. The presence of an Integrated Heatspreader (IHS) on the CPU greatly facilitates the application of the thermal compound. This method minimizes the chances of air bubbles and eliminates insufficient contact in the die area because of unwanted build-up in the periphery. Spreading compound over the entire heat spreader will simply result in a less even, thicker spread, leading to less heat transfer. |

Thermal paste is ranges between a light gray or even a silver metallic color. You can see from the picture below there are some distinct differences between the four thermal Compounds in the lineup.

From Left to right: Intel OEM, OCZ Freeze, Arctic Silver 5, and Thermalright Chill factor III

Important Note: It typically can take up to 250 hours to burn in a thermal paste to maximum efficiency. According to OCZ:

“Unlike silver-based compounds, OCZ Freeze requires no curing time and is non-electrically conductive. Optimal results will be achieved after application.”

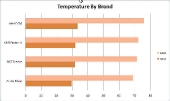

Results:

The results are surprising. Even though the OCZ required significantly less preparation and effort, it significantly outperformed the stock grease. The test system is very unique in that there are very high heat conditions in a very small area. While this is not ideal for most situations. It does provide a good test bed for thermal compound.

Summary:

OCZ has an established name in the memory market, this endeavor into the thermal compound is not their first but it certainly gives them a good foothold. OCZ FREEZE was very close to the significantly more expensive Arctic Silver 5, and it provided a significantly less complicated installation process. Given the value, and the impressive performance I am awarding this the TechwareLabs Approved Hardware Award.

Well, this is very useful for those who own a personal computer, also want to protect it from being burnt.